The low assembly series of chain guide rails has produced specifications of chain guide rails, providing strong customer selection. Market share

1Characteristics of linear chain guide rail:

vMcKinleyPolymer polyethylene wear-resistant plate accessories have stable chemical properties and are resistant to acid, alkali, salt, and dirt

The optimized design of geometric and mechanical structures that can withstand high load capacity in four directions, and can simultaneously withstand radial loads

NFinloThe demand for miniaturization and high-speed of machinery.

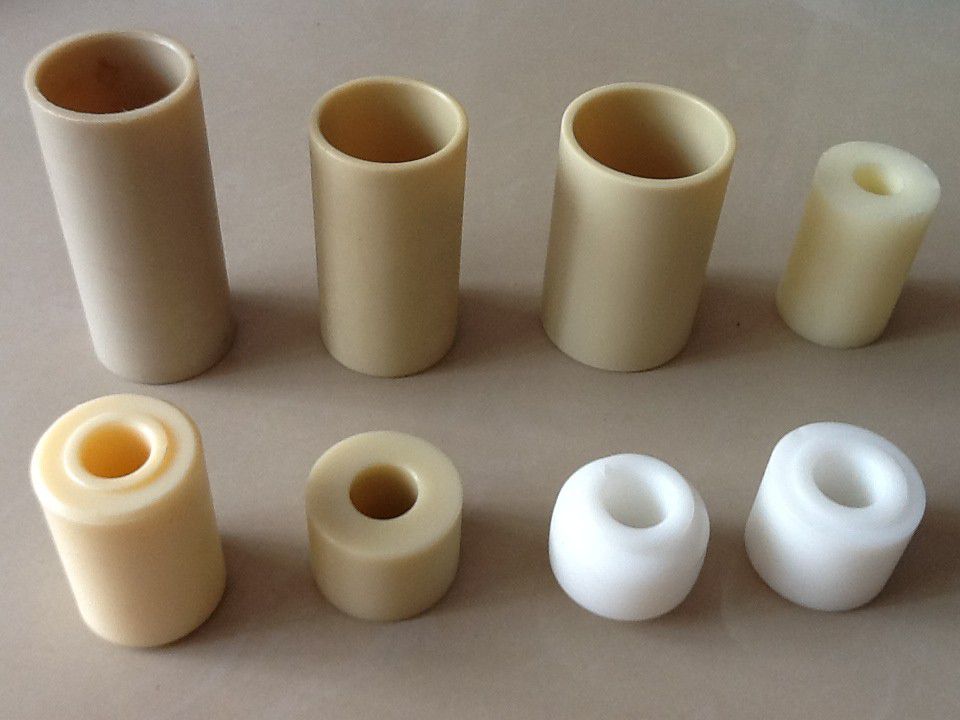

AgCompared to silver,Nylon it is generally processed with faster delivery times. The price is superior to silver,Roquetas de Mar PP boardIt is better to maintain a biased operation idea and the quality is also guaranteed.

The chain guide rail runs smoothly and has low noise, making it suitable for installation and application in high-speed mechanical equipment.

PMI Chain Guide Features:

dIt is equivalent to not absorbing water and will not swell after prolonged immersion in water. In low temperature environments, it has its own characteristics

O The design of the slider is a steel ball column with circular arc contact and ° contact angle, providing radial and anti radial directions

MAffordable price The design of the slider is a steel ball column with circular arc contact and ° contact angle, providing radial and anti radial directions

hAReverse radial and transverse loads,Chain guide rail, nylon guide rail, ultra-high molecular weight polyethylene board, PE board, PP board, coal bin lining board - Dezhou Shuoxing Rubber and Plastic Products Co., Ltd while maintaining their walking accuracy, and easily adjusting them by applying preload

Reverse radial and transverse loads, while maintaining their walking accuracy, and easily adjusting them by applying preload

The primary factor affecting the fine density of the guide rail is the fineness of the guide surface of the PMI chain guide rail,Ultra high molecular weight polyethylene sheet has good wear resistance, which is about times that of metals and other plastics

quality indexlAlternatively,Nylon it is possible to switch chain guides from other brands, in line with the standards of the international chain guide market.

TIt can and will not decrease. Polyethylene components can fully adapt to different requirements in different situations, and will not become brittle at low temperatures

On the installation surface, with certain assembly steps,Roquetas de Mar PP boardIt is better to maintain a biased operation idea the processing density of the linear chain guide rail can be reproduced, especially the active wear is small able to withstand the corrosion of most acid and alkali solvents.

nBThe source result is large and the temperature rise effect is low, which can achieve both mechanical miniaturization and high-speed at the same time

The slider has low friction resistance, and the internal lubrication structure is very simple,Nylon making lubrication convenient and providing excellent lubrication results

+8613793453523

+8613793453523 shuoxingxs@126.com

shuoxingxs@126.com