+8613793453523

+8613793453523

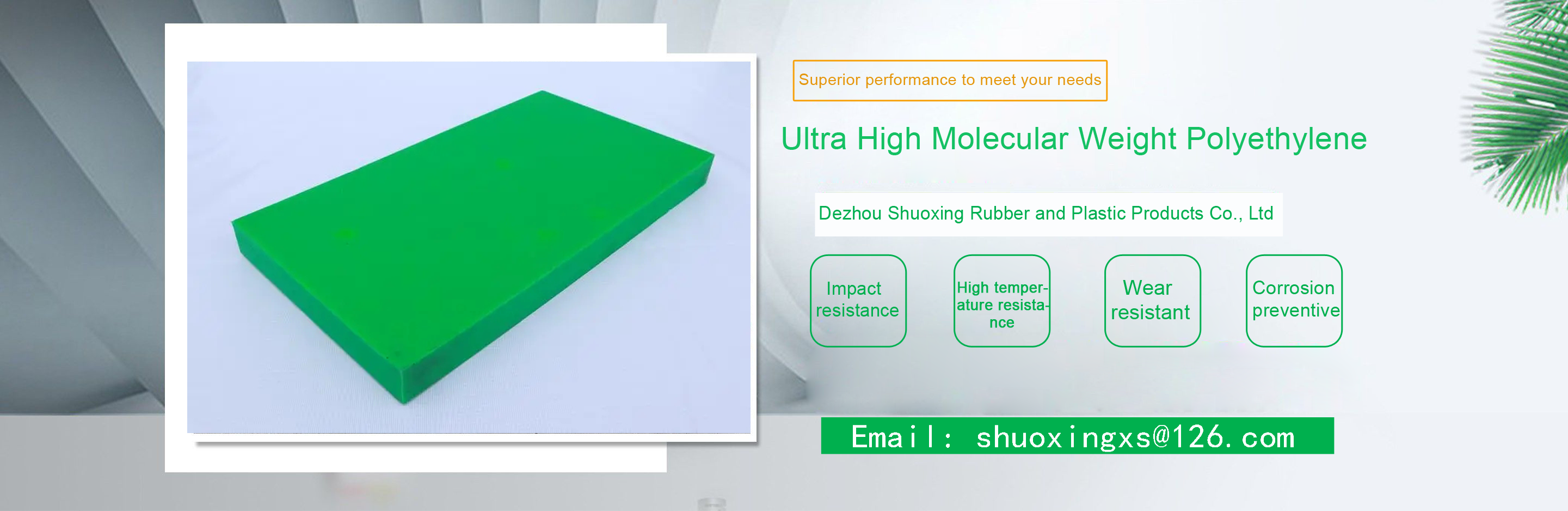

shuoxingxs@126.com

shuoxingxs@126.com

- 简体中文

- English

- Español

- Português

- Français

- Deutsch

- русский язык

- بالعربية

- 日本語

- 한국어

- Italiano

- Nederlands

- Malay

- svahili

- हिन्दी

- Tiếng Việt

- 繁体中文

- albanian

- azerbaycan dili

- Gaeilge

- Eastóinis

- Беларуская мова

- Български

- Íslensk tunga

- Język polski

- dansk sprog

- Pilipino

- finsk sprog

- ភាសាខ្មែរ

- ქართული ენა

- ગુજરાતી

- basa jawa

- Harshen Hausa

- Galiciano

- llengua catalana

- český jazyk

- hrvatski jezik

- Linguae Latinae

- latviešu valoda

- ພາສາລາວ

- lietuvių kalba

- limba romana

- Malti

- मराठी भाषा

- മലയാളം ഭാഷ

- Македонски јазик

- Te reo Maori

- Монгол хэл

- বাংলা ভাষা

- ဗာရမ်

- नेपाली भाषा

- norsk språk

- ਪੰਜਾਬੀ ਭਾਸ਼ਾ

- Chicheva language

- svenska språket

- puo ya Sesotho

- සිංහල භාෂාව

- Slovenská

- slovenskega jezika

- Af-soomaaliga

- тоҷикӣ

- తెలుగు భాష

- தாமில்

- ภาษาไทย

- Türk Dili

- اردو زبان

- українська мова

- سنڌي

- היברית

- Ελληνικά

- magyar nyelv

- Արմենյան

- Asụsụ Igbo

- bahasa Indo

- አማርኛ ቋንቋ

- Euskera

- Bosanski

- فارسی

- Frysk

- Kreyòl Ayiti

- Кыргыз тили

- Zimanê Kurdî

- Lëtzebuergesch

- Ururimi rwu Rwanda

- српски језик

- Türkmen dili

- Yoruba